As a measure of scale, the engraver cutting tool has a diameter of 6mm.

So far it seems to be working very well ... !

So far it seems to be working very well ... !

So far it seems to be working very well ... !

So far it seems to be working very well ... !

And here is what it looks like more recently:

And here is what it looks like more recently: Since this photo was taken, all of the buttons and annunciators have been correctly placed and any and all spaces have now had their appropriate fittings made. The annunciators will all be backlit with their correct colours and each button will have their bracket attached, ready for wiring. Before this is done though, we're currently in the process of colouring each 'flow' area of the overhead in the appropriate shades of green or blue. This morning was spent developing the right technique to do this accurately and was very time-consuming, even on just a small section, but now that a method has been successful the rest should be much quicker.

Since this photo was taken, all of the buttons and annunciators have been correctly placed and any and all spaces have now had their appropriate fittings made. The annunciators will all be backlit with their correct colours and each button will have their bracket attached, ready for wiring. Before this is done though, we're currently in the process of colouring each 'flow' area of the overhead in the appropriate shades of green or blue. This morning was spent developing the right technique to do this accurately and was very time-consuming, even on just a small section, but now that a method has been successful the rest should be much quicker. And here are the gauges that've been fitted:

And here are the gauges that've been fitted:

Note: The graphics on the last temperature gauge are actually properly positioned and readable - the angle at which the photo was taken is just deceiving.

Note: The graphics on the last temperature gauge are actually properly positioned and readable - the angle at which the photo was taken is just deceiving.

Included in the wiring schedule over the next few weeks will hopefully be a fair amount of backlighting work too.

Included in the wiring schedule over the next few weeks will hopefully be a fair amount of backlighting work too.  I machined the base section of the handle from some 8mm thick clear acrylic which I then painted with a couple of light coats of red paint. The upper section of the handle is actually made from two 3mm thick red transluscent acrylic, and then I engraved the lettering into the top layer, which my son 'in-filled' with white paint. It turned out great, and I am very pleased with it.

I machined the base section of the handle from some 8mm thick clear acrylic which I then painted with a couple of light coats of red paint. The upper section of the handle is actually made from two 3mm thick red transluscent acrylic, and then I engraved the lettering into the top layer, which my son 'in-filled' with white paint. It turned out great, and I am very pleased with it. Ultimately there will be some high-intensity red LEDs fitted inside the handle, which will light up the whole handle whenever there is an engine fire. The shaft is a short length of 1/4" brass rod. Yes, I will bore a hole down its centre for the LED wires when I fit them!!!

Ultimately there will be some high-intensity red LEDs fitted inside the handle, which will light up the whole handle whenever there is an engine fire. The shaft is a short length of 1/4" brass rod. Yes, I will bore a hole down its centre for the LED wires when I fit them!!!

Because of differences in the size of the old monitor and the new one, I've temporarily had to remove the Speed Selector Knob, which accounts for the small hole on the left side of this photo. Strictly speaking this should actually be positioned at the top right of the gauge, but that would put it right in the middle of the new LCD screen! A solution will be found for this later on.

Because of differences in the size of the old monitor and the new one, I've temporarily had to remove the Speed Selector Knob, which accounts for the small hole on the left side of this photo. Strictly speaking this should actually be positioned at the top right of the gauge, but that would put it right in the middle of the new LCD screen! A solution will be found for this later on. Thin strips of MDF (approximately 3.2mm thick) were then cut and formed into the correct arc by wetting them with hot water and clamping them across the top edge of the side wall. Once they were damp they went soggy and could be formed into shape very easily. After this process, they were then left to dry and harden for several hours.

Thin strips of MDF (approximately 3.2mm thick) were then cut and formed into the correct arc by wetting them with hot water and clamping them across the top edge of the side wall. Once they were damp they went soggy and could be formed into shape very easily. After this process, they were then left to dry and harden for several hours.

The notches in the sides, and the slot in the centre, ideally should be done after the correct shape has been formed as detailed above. If done before the hot wet forming, they tend to twist too much.

Below is an overall view of the unit once the document holders were fitted. There's actually an artificial bottom in the outer one because the smaller sheets kept disappearing out of sight!!!

This picture shows the clamps holding the rubber strips in place whilst the glue was drying.

Here's the almost completed throttle quadrant before the painting of the flap knob, reverser levers, and park brake lever.

And this is it with just the thrust reverser levers to paint.

Another view showing how the manual and approach charts sit in their pockets.

And the final photograph shows the completed throttle console fitted into place in the simulator. You might also notice the addition of two new pushbuttons, a red switch safety catch, and a black handle.

Note: The rest of the centre console with the radios and audio systems is not yet complete, but is sitting in place so as to make things look a bit prettier!!!!

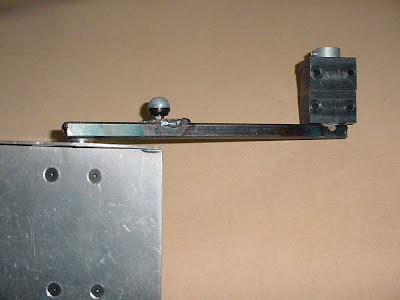

The next photograph shows the cross-arm which links the Captain’s rudder pedals to the F/O’s pedals.

The next photograph shows the cross-arm which links the Captain’s rudder pedals to the F/O’s pedals. Here's a better view of the entire push-rods and cross-arm assembly.

Here's a better view of the entire push-rods and cross-arm assembly. Here's how the main push-rod ball joint is attached.

Here's how the main push-rod ball joint is attached. This is the piece you put your foot into. Note the spring that gives a ‘feel’ to the brakes. You can also see the wire push-rod that operates the arm on the pot which is connected to the brake axis.

This is the piece you put your foot into. Note the spring that gives a ‘feel’ to the brakes. You can also see the wire push-rod that operates the arm on the pot which is connected to the brake axis. One completed assembly as viewed from the top.

One completed assembly as viewed from the top. And, of course, one completed assembly as viewed from underneath.

And, of course, one completed assembly as viewed from underneath. Next is an under-pedal view showing the bearing blocks and the brake axis pot with push-rod and return spring. I used acetal for the bearing blocks because it's easy to machine, dimensionally stable, and has reasonable wear properties.

Next is an under-pedal view showing the bearing blocks and the brake axis pot with push-rod and return spring. I used acetal for the bearing blocks because it's easy to machine, dimensionally stable, and has reasonable wear properties.  Brake axis pot from a different angle.

Brake axis pot from a different angle. Followed by an even better angle of the brake mechanism.

Followed by an even better angle of the brake mechanism. This is another angle of the pedal bearing blocks. The collars which prevent the shaft from moving sideways in the bearing blocks is just a piece of thick walled pipe with a screw threaded into the side of it.

This is another angle of the pedal bearing blocks. The collars which prevent the shaft from moving sideways in the bearing blocks is just a piece of thick walled pipe with a screw threaded into the side of it. Bearing blocks again, and note the screw with nuts either side of the shaft . This allows for adjustments to be made with regards the angle of the pedal to the shaft when the brakes are released.

Bearing blocks again, and note the screw with nuts either side of the shaft . This allows for adjustments to be made with regards the angle of the pedal to the shaft when the brakes are released. This shows the countersunk screws going through the rudder pedal to the bearing blocks. Also, you can see the bearing blocks at the bottom of the rudder arm.

This shows the countersunk screws going through the rudder pedal to the bearing blocks. Also, you can see the bearing blocks at the bottom of the rudder arm. Here's a better view of the bearings and collar.

Here's a better view of the bearings and collar. Both completed assemblies.

Both completed assemblies. The next few photos show a trial setup designed to test operation. Note the different type of rod-ends here. These were eventually found to be unsuitable because they're effectively sprung-loaded internally, which produces a sloppy action when using the rudder pedals. The round grey rod-ends in most of the previous photos are perfect for the job.

The next few photos show a trial setup designed to test operation. Note the different type of rod-ends here. These were eventually found to be unsuitable because they're effectively sprung-loaded internally, which produces a sloppy action when using the rudder pedals. The round grey rod-ends in most of the previous photos are perfect for the job. Another angle on the trial setup.

Another angle on the trial setup. And yet another one, to better show how all the bits and pieces fit together.

And yet another one, to better show how all the bits and pieces fit together. The last photograph shows a trial setup in the actual simulator, with wooden blocks being employed instead of the lovely aluminium pedals which eventually replaced them. This trial was just to get a better feel for the angles and range of movement.

The last photograph shows a trial setup in the actual simulator, with wooden blocks being employed instead of the lovely aluminium pedals which eventually replaced them. This trial was just to get a better feel for the angles and range of movement.

100mm x 50mm beams were used as a base so as to keep the floor high enough to allow for some underfloor mechanisms and cables to be placed (and hidden!) there at a later stage.

This is the first of many modules and everything is screwed together rather than nailed, just in case it has to be moved in years to come. Cockpits don't fit through standard doorways very nicely!

Here you can see the side frames taking shape and the central console holds the mounting bases for the Captain and F/O flight instrument monitors.

A pair of old car seats were employed for the Captian and F/O. It was necessary to slightly modify the front edge of each seat with a cut-out (to allow the control yoke to fit when the seat is positioned well-forward at the same time as the yoke is being pulled well-back) before they were re-upholstered.

Here you can see the initial parts of the glare shield under construction with the F/O flight instruments monitor sitting in place.

And here is a trial fitting of the control columns ...

This photograph shows temporary yokes having been fitted to the control columns. A continuous chain links both yokes together with precision. Just beyond these you can also see that a trial pair of flight instrument panel cut-outs have been fitted.

The next phase of construction will follow shortly ...